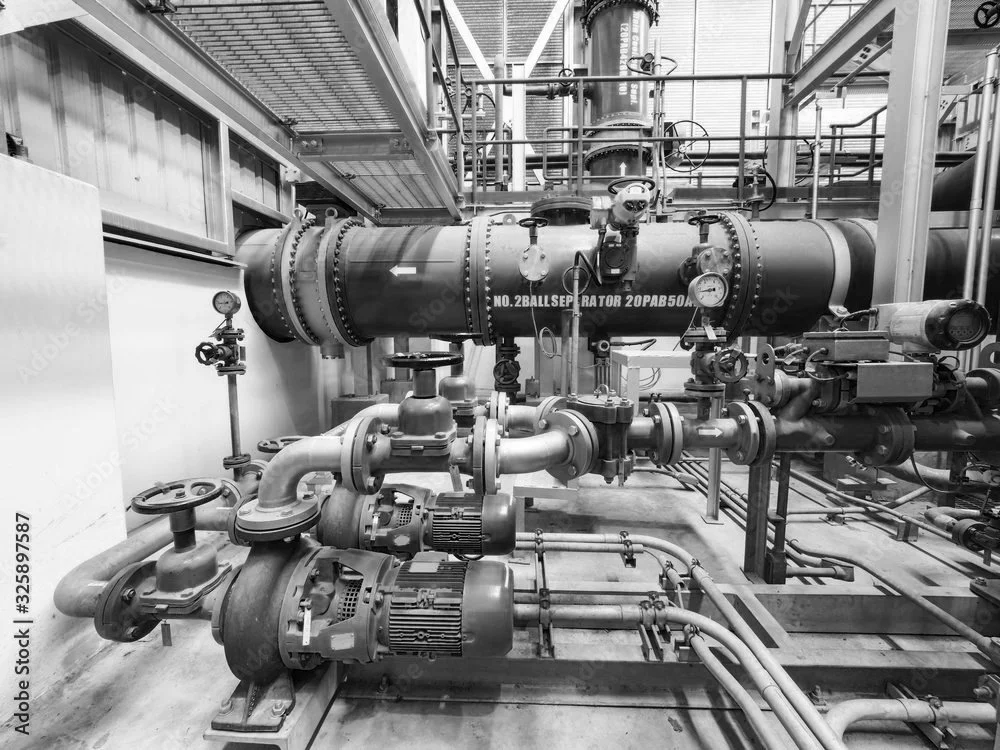

Condensate Recovery

Our expertise in condensate recovery can transform your steam system, cutting energy consumption and operational costs while minimizing environmental impact. By capturing and reusing condensate, we help you reduce water and chemical usage.

With our specialized knowledge regarding optimized condensate recovery, we empower you to maximize your steam system's efficiency and ensure its longevity.

Boost Efficiency With Steam Condensate Recovery

Reduced carbon footprint

Increased equipment life

Reduced system downtime

Reduced maintenance costs

Increased system capacity

Water and associated treatment savings

Condensate contains a significant amount of sensible heat, accounting for approximately 10% to 30% of the initial heat energy in steam. By feeding your boiler with high-temperature condensate, you can maximize boiler output, as less energy is required to transform water into steam.

When condensate is efficiently recovered and reused, you can potentially reduce your boiler fuel needs by 10% to 30%. Don't let valuable energy go to waste.

Condensate System Optimization Maximizes Energy Usage

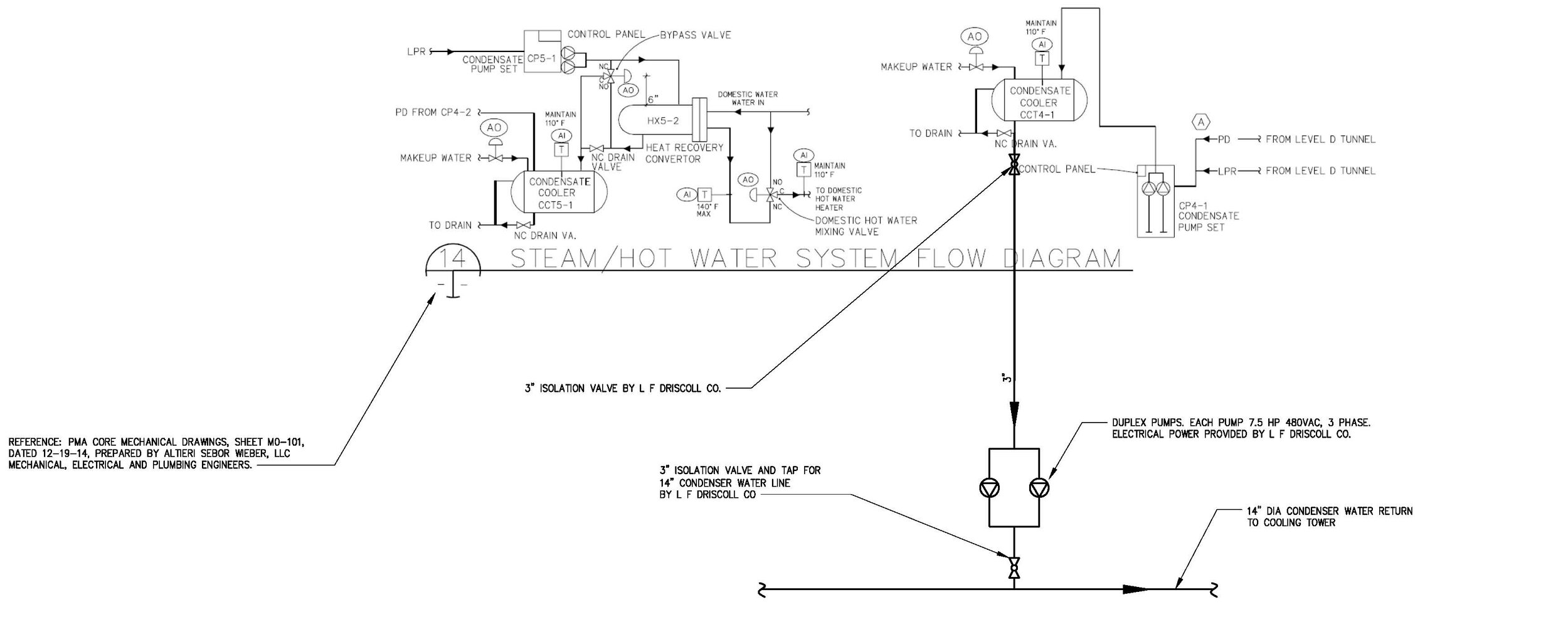

High pressure condensate flash steam utilization captures and repurposes otherwise wasted energy

Recovered high pressure condensate flash steam can be used for heating, process applications, or to generate power

By effectively harnessing this energy, you can reduce your energy consumption and lower operational costs

Condensate return unit repairs and replacements maintain the efficiency and reliability of steam systems

Timely repairs and retrofits can lead to energy savings and reduced operational costs

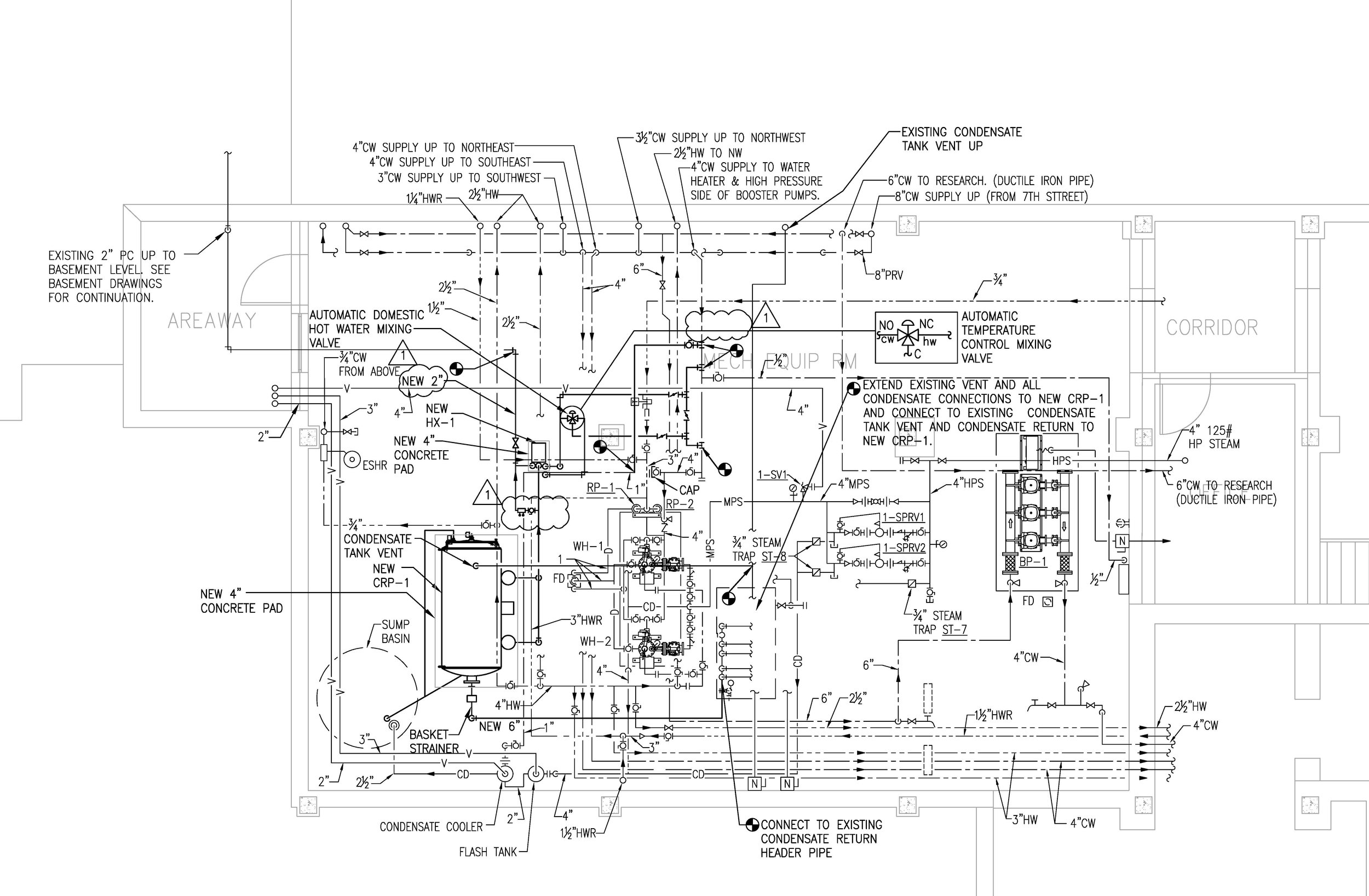

Accurately Measure and Monitor your System’s Condensate

By accurately measuring the amount of condensate returned to the boiler, we help ensure that the system operates at optimal efficiency. Condensate metering also aids in detecting leaks and identifying areas for improvement in the steam distribution network. Metering is an essential tool for maintaining the health and performance of your steam system, leading to significant savings and sustainability benefits.

Improve Safety and Save Energy with Proper Thermal Insulation

The lack of proper insulation on condensate systems wastes energy, creates health and safety issues, and produces unnecessary carbon emissions.

We survey systems to specify and install conventional insulation as well as removable insulation covers (RICs), which maintain the efficiency of the heating and cooling systems.

Proven Condensate Recovery Expertise

Case Study: New Monitoring Solution and Condensate Heat Recovery System

Case Study: Comprehensive Condensate System Assessment

Case Study: Troubleshooting Condensate Return Issues in Unit Ventilators at New York High Schools

Case Study: Modernization of the Philadelphia Museum of Art's Steam System Leads to Massive Savings

Webinar: Steam Condensate Collection

White Paper: Condensate Return Analysis

Learn About Our Other Steam System Solutions

Speak to an Expert About Optimizing Your Steam Condensate Recovery System

info@steammgt.com

1-800-731-0131