Steam Distribution

As your partner, we leverage our years of experience to work with you on identifying savings opportunities, issues and deficiencies within your existing steam distribution system, and quickly address areas of opportunity within your facility with proven products and engineering.

From introduction to installation, SMI provides consistent support, communication, and documentation to ensure that at the project’s completion the steam distribution system is running more efficiently reducing utility costs and your carbon footprint is realized.

Investing in regular steam trap maintenance, including timely repairs and replacements, is crucial for maximizing the efficiency and longevity of your steam system.

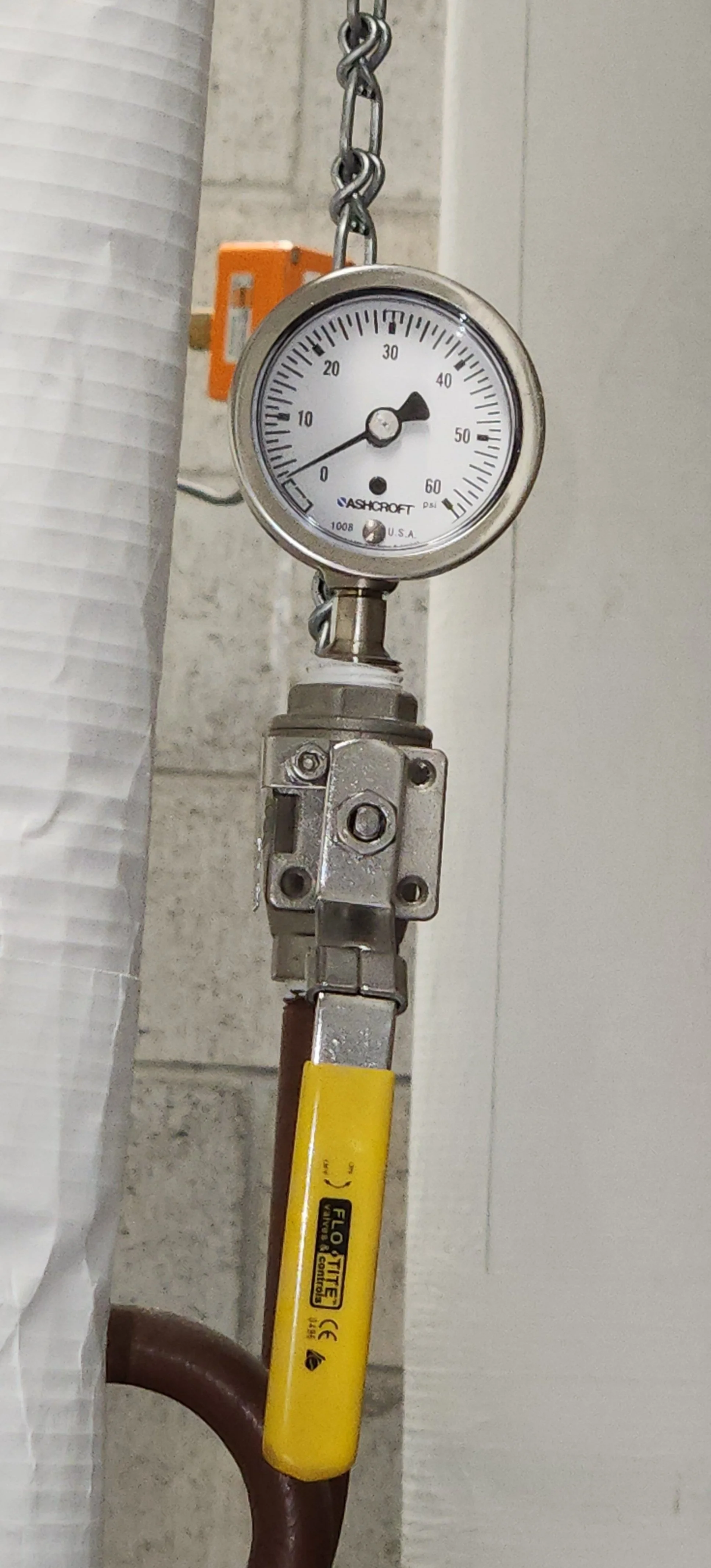

Steam Trap Testing is Essential for Optimizing System Performance

Increased Boiler Fuel Consumption

Steam Venting

Condensate Backup

Water/Steam Hammer

Steam Point of Use Equipment Not Performing Properly

Signs You Need a Steam Trap Replacement:

Performing annual testing identifies failures and losses within the system. However, if the system is only tested once a year or longer, a steam trap failure could go unnoticed for a long period of time.

We incorporate the latest technology to continuously monitor your steam trap operation and collect data in real-time for analysis. This level of visibility into the operational status of the steam trap population is critical to the efficient operation of your steam system.

Make the Most Out of Your System’s Energy With Steam Trap Monitoring

No Shutdown Required for Installation

Remote Monitors (hardwiring not required)

Accurate Data in Real Time

Identify Faulty Steam Traps Immediately

Potential Utility Rebate Incentives

Simple Maintenance

The lack of proper insulation on steam and hot water systems wastes energy, creates health and safety issues, and produces unnecessary carbon emissions.

We survey systems to specify and install conventional insulation as well as removable insulation covers (RICs), which maintain the efficiency of the heating and cooling systems.

Improve Safety and Save Energy with Proper Thermal Insulation

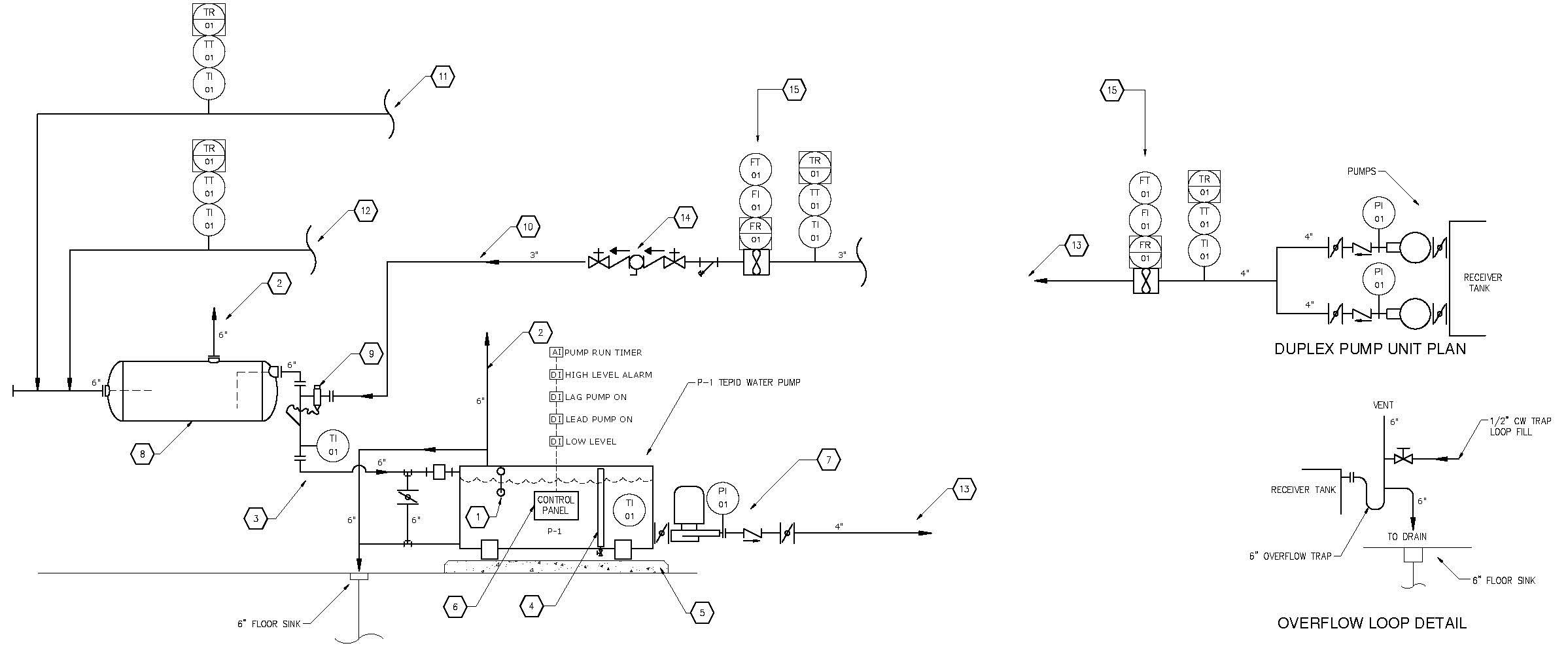

Metering services include recommendations on system measurement points, meter specifications, installation, digitization through PLC, associated monitoring control systems, and commissioning of the system to ensure you have reliable and precise data to manage your steam system effectively. Accurate metering provides crucial data that helps you:

Manage Your Steam System Effectively with Steam and Condensate Metering

Monitor System Performance

Control Energy Costs

Ensure Accurate Billing

Enhance Environmental Sustainability

Improve System Capacity & Ensure Efficiency

Mitigate compliance risk

Control valve installation is a critical aspect of steam and hydronic systems, playing a pivotal role in regulating the flow and pressure of fluids. Precise control is essential for maintaining desired temperatures, pressures, and flow rates, which directly impacts the system's performance and longevity. We ensure that the right control valve is selected for each application and that it is installed correctly, preventing issues that could lead to costly repairs or downtime.

Professional Control Valve Installation Services

By automating the control of steam pressure, we help you achieve significant energy savings, reduce wear and tear on equipment, and enhance process control. Minimizing steam pressure reduces all steam losses.

Optimizing Steam Pressure

Our Experts Design Improvements to Steam Networks That Maximize Energy Savings, Reduce Operational Costs, & Enhance Equipment Longevity

Optimizing the application design of your steam distribution system is key to enhancing efficiency and reliability. We engineer and implement distribution piping changes that optimize the system’s energy use. Additionally, effective insulation and strategic placement of steam traps and condensate return lines ensure optimal steam delivery and recovery.

Proven Steam Distribution Expertise

Case Study: Efficiency Enhancements in Boston Lead to 5 Million Gallons of Annual Water Savings and Significant CO2 Reductions

Case Study: Automation Project Provides Steam System Efficiency and Control Enhancements at Weyerhaeuser Veneer Mill

Case Study: Smart Steam Management: How Data-Driven Insights are Transforming Boston Children’s Hospital’s Energy Efficiency

Case Study: Steam Trap and Pipe Insulation Upgrades Save an Illinois VA Hospital $100k in The First Year

Case Study: Steam and Valve Retrofit Project Provides Long Beach Public Schools with Energy Savings and Reduced Emissions

Case Study: Norfolk Naval Shipyard Piping and Steam Trap Upgrades

Case Study: Comprehensive Pipe Insulation Project at a Texas Federal Correctional Institution

Webinar: Steam Systems, An Operational Cost/Benefit Analysis

Webinar: Industrial Steam System Assessments

White Paper: Pressure Reducing Valves

Learn About Our Other Steam System Solutions

Speak With an Expert About Improving Steam Distribution in Your Facility

info@steammgt.com

1-800-731-0131