Case Study

Condensate Recovery System Retrofit at the Philadelphia Museum of Art Saves Over 14 Million Gallons of Water Annually

SMI Impact

Annual sewer and water cost savings: $68,785

Condensate energy cost savings: $80,982

Annual water and sewer savings: 14,680,000 gallons

Customer

Built in 1928, the Philadelphia Museum of Art was modernizing and expanding their facility by 90,000 square feet to increase it’s gallery and public spaces.

Conditions

The Philadelphia Museum of Art (PMA) receives steam from a district heating system owned and operated by Antin Infrastructure Partners, Inc., which also supplies nearby hospitals and the University of Pennsylvania. Under PMA’s agreement, the museum is not required to return steam condensate to the district plant. As a result, condensate from the museum’s main building was discharged directly to the sewer. Building codes required the condensate to be cooled before discharge, which was achieved by mixing it with potable water—lowering the temperature from 180°F to 110°F. This process led to significant waste of both water and thermal energy, as well as avoidable sewer charges.

Solution

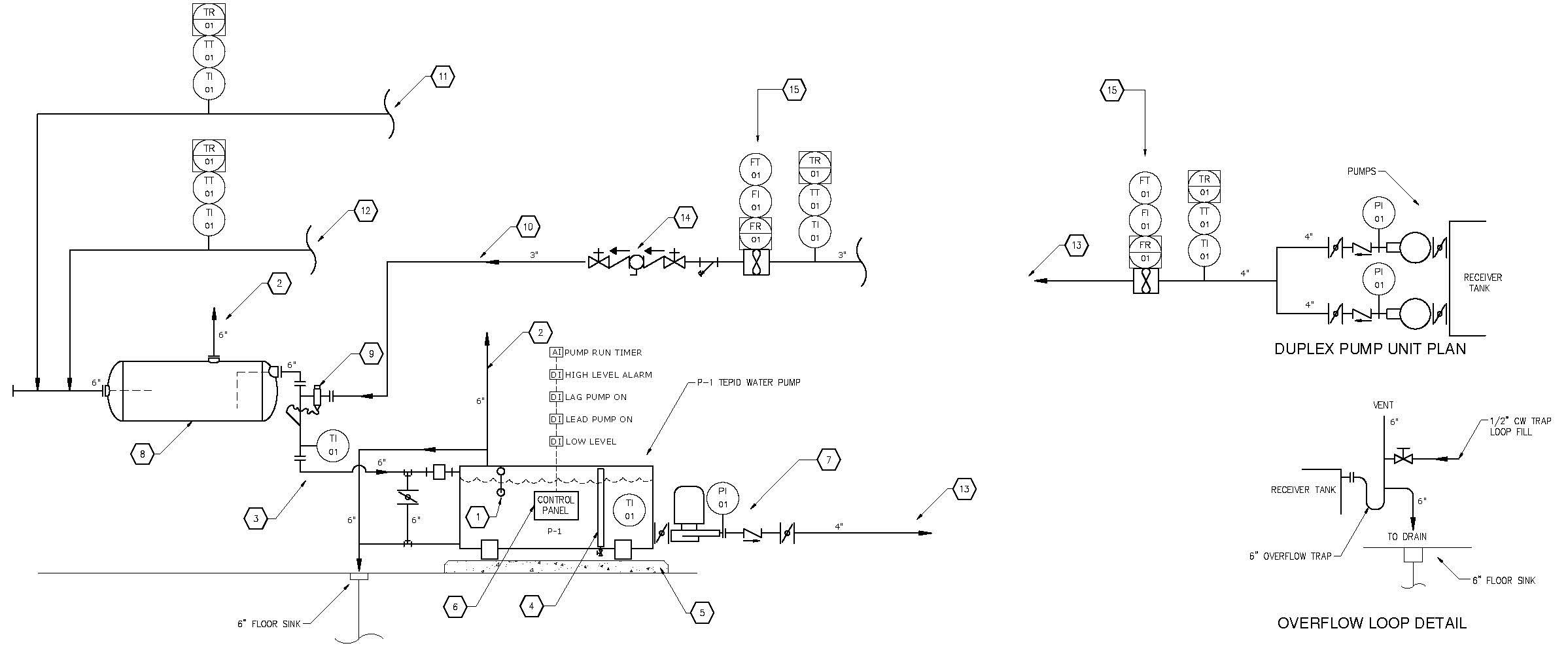

The PMA steam condensate system was retrofitted with collection/storage and conveyance equipment to recover this wasted water and use it to offset the makeup water being used in the facility air conditioning cooling towers.

The steam condensate water is essentially distilled water since the steam generating process eliminates most of the total solids in the water. The mixing of the steam condensate with potable water to lower its temperature ends up with an ideal water quality to be used for end user purposes such as cooling tower makeup water, plumbing toilet flush water and landscape irrigation water, thus offsetting part of the costs for purchased water. This represents a potential opportunity to recover not only the condensate water but also the cooling water being discharged, which represents energy and water cost savings for the end user of the district heating systems.

In this case the recovered water is being used for makeup cooling tower water. The PMA cooling towers are used to remove heat from the building air conditioning system. Cooling a stream of water to a lower temperature using evaporation does this. Therefore, this evaporated water in the cooling towers needs to be continually replaced in the cooling tower process.

Schedule an Assessment of Your Facility

info@steammgt.com

1-800-731-0131

One Lincoln Street, Suite 2900

Boston, MA 02111